Riyadh Saudi Arabia: The K-BOS results in more than a 94% reduction in the probability of a blowout in surface drilling applications according to a detailed industry study. At this year’s IPTC 2022 in Riyadh Saudi Arabia, the paper (IPTC-22152-MS) was presented showing a detailed sensitivity analysis to determine the reduction in the probability of a blowout provided by adding the K-BOS to a surface drilling application. This paper compliments previous work done by NASA’s Johnson Space Center which used data from US Gulf of Mexico deep water operations to determine that the K-BOS provides a multiple orders of magnitude reduction in blowout probability in subsea applications.

The K-BOS provides a dramatic improvement in well control certainty:

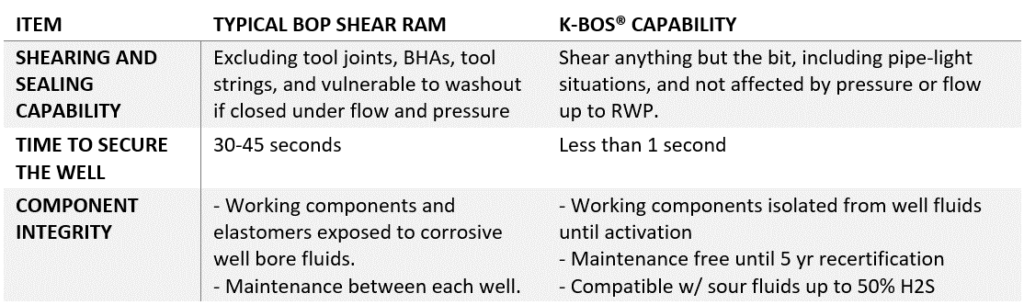

Shown above: A table compares the capability of a typical BOP vs the K-BOS capability, highlighting dramatic improvements in terms of shearing and sealing capability, time to secure the well, and component integrity.

More about the paper:

With the goal to exhibit leadership in industry process safety, North Caspian Operating Company (NCOC), Eni, and Kinetic Pressure Control have collaborated to evaluate the feasibility and potential process safety benefits from use of the Kinetic Blowout Stopper (K-BOS®) technology in High-H2S and high-pressure drilling and completions and intervention applications from artificial islands in Kashagan field. The study focused on efforts to detect any showstoppers for the application of K-BOS, quantify the reduction in the blowout probability due to its application, and summarize the information currently available about the technology.

Kinetic’s proprietary seal design, that allows for reliable use of elastomeric materials compatible with up to 50% H2S fluids, is directly scalable to the 18-3/4″ size and sealing pressures of up to 20,000 psi.

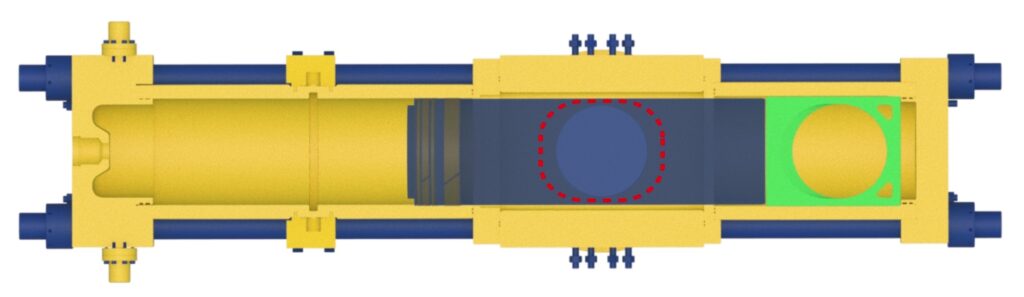

Shown Above: A cut-away view illustration of the 13-10M K-BOS as seen from above the device looking down the wellbore. The semi-transparent dark blue element has been actuated across the wellbore, and the red dashed line illustrates the seal location.

Using the Eni proprietary e-wise™ fault tree analysis approach, a quantitative risk assessment was performed to compare the probability of a blowout in Kashagan field using conventional BOP systems to the probability of a blowout with the K-BOS added to the stack. The study also reviewed OEM provided operating procedures, a risk assessment for running the equipment, as well as a feasibility study regarding any height restrictions in the BOP stack and the position of the K-BOS in the stack. The impact of alternative equipment for risk reduction such as additional redundancy was also assessed.

The application of the 13 5/8″ 10M K-BOS system during reservoir drilling, completion and intervention operations significantly reduces the probability of a blowout by at least an order of magnitude. For drilling operations in the most challenging Rim portion of the reservoir, the blowout probability decreases by more than 90% and the residual value is below the blowout frequency for Producing Wells.

The improved shearing/sealing capacity and reduced closure time provided by the K-BOS enable a reduced likelihood of a blowout and enhance the risk profile for the oil and gas industry.

The detailed paper may be purchased for download on SPE’s onepetro.org please use paper Number: IPTC-22152-MS for reference.

Shown above, an artificial island used for drilling in the Kashagan field.