current well control paradigm

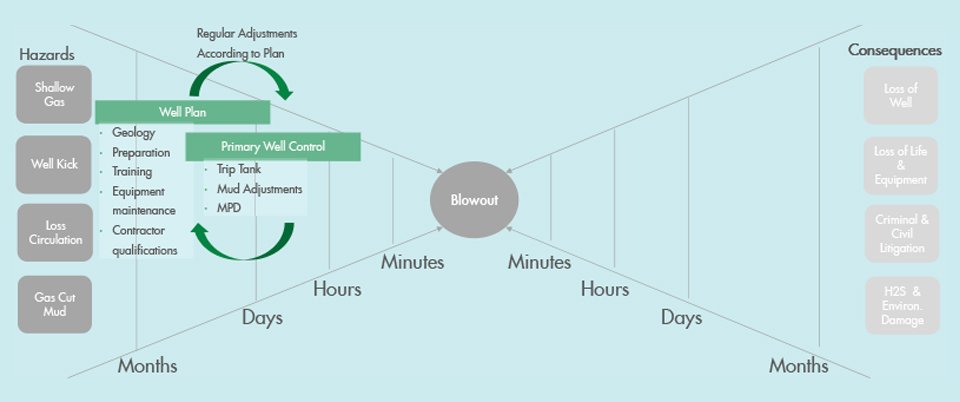

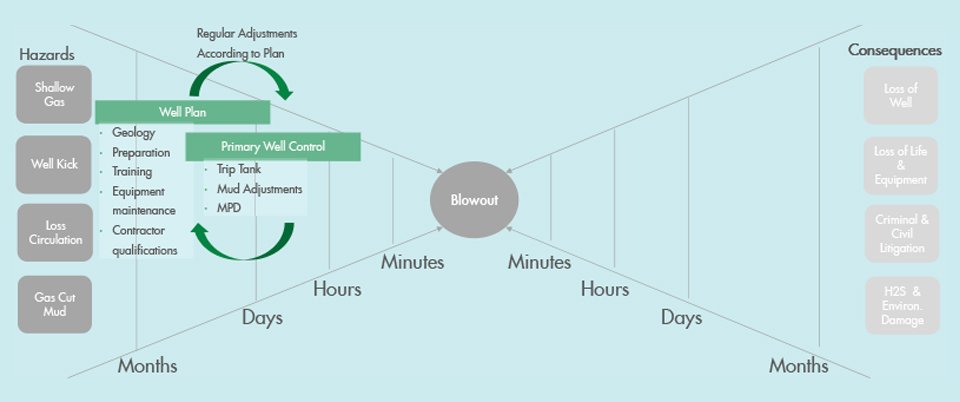

Drillers circulate drilling fluid, consisting from sea water to highly specialized mud, down the drill string and up the annulus of the well bore. Primary Well Control is achieved by maintaining the effective circulation density of the drilling fluid in the well such that the hydrostatic pressure in the well is more than the formation pressure, but less than the fracture gradient. Under normal drilling circumstances this prevents an undesired influx of hydrocarbons into the wellbore.

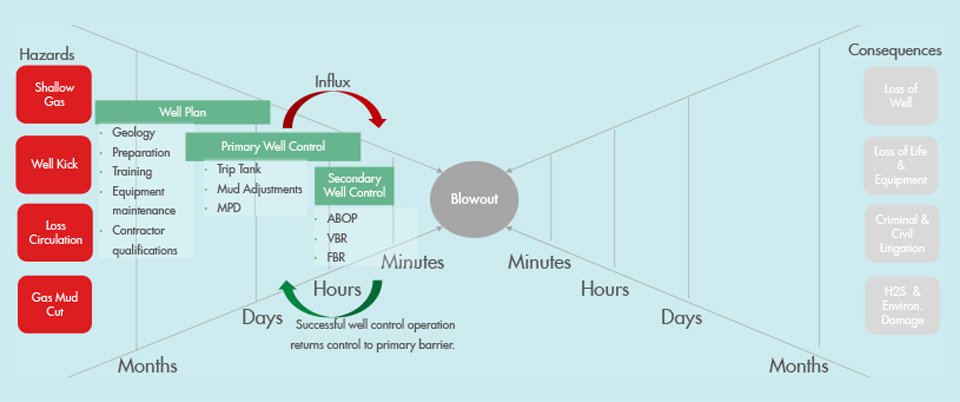

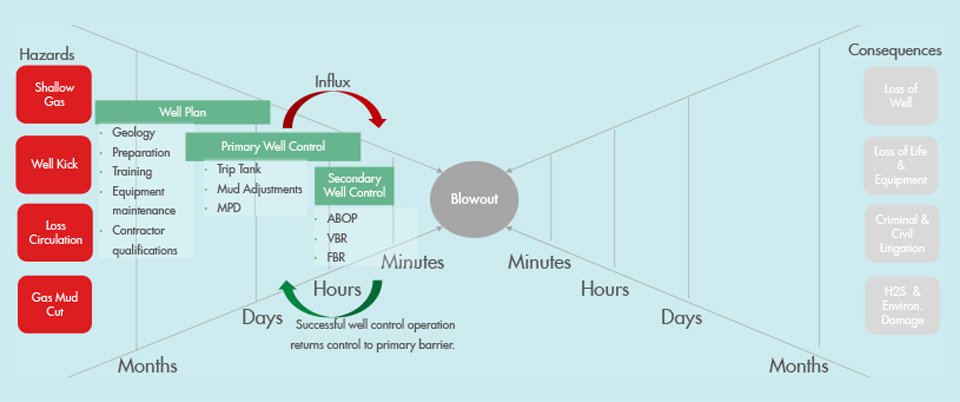

Unanticipated hazards such as shallow gas, a loss of circulation, gas cut mud, or higher than expected formation pressure can result in an undesired influx of hydrocarbons into the well bore known as a “kick.” Once drillers detect a kick, they close the annular BOP and/or pipe ram BOP which increases hydrostatic pressure and prevents further influx of hydrocarbons into the well. During this activity known as Secondary Well Control, adjustments are made to circulate the kick out of the well, increase mud weight to match formation pressure, and continue drilling the well.

Coil Tubing, Hydraulic Workover or Snubbing, and well intervention operations are regularly performed with hydrocarbons present in the well under full formation pressure. In these cases, the BOP is an integral part of the operation and is used continuously to control the well.

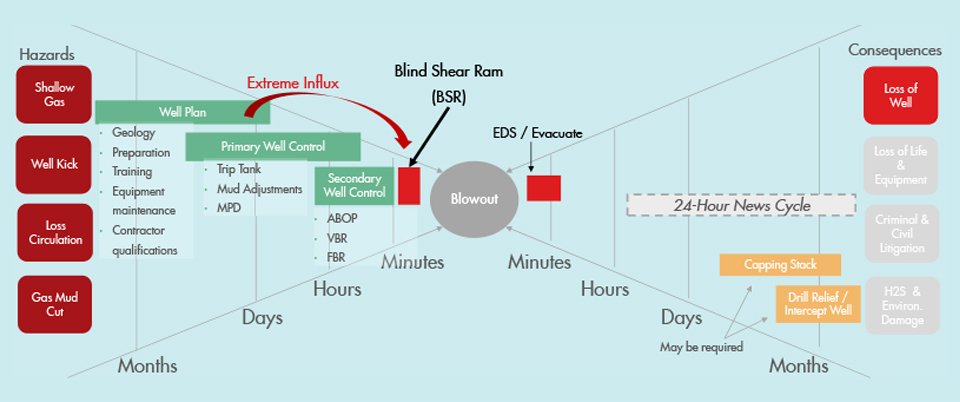

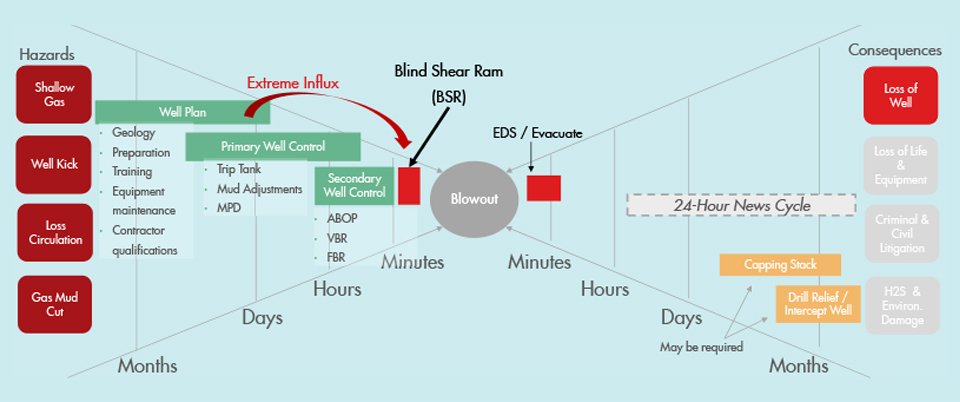

In rare cases, the secondary well control means are insufficient to maintain well control. In these situations, the blind shear ram, a special BOP ram outfitted with cutting blades and seals, is activated to shear the drill string and shut-in the well.

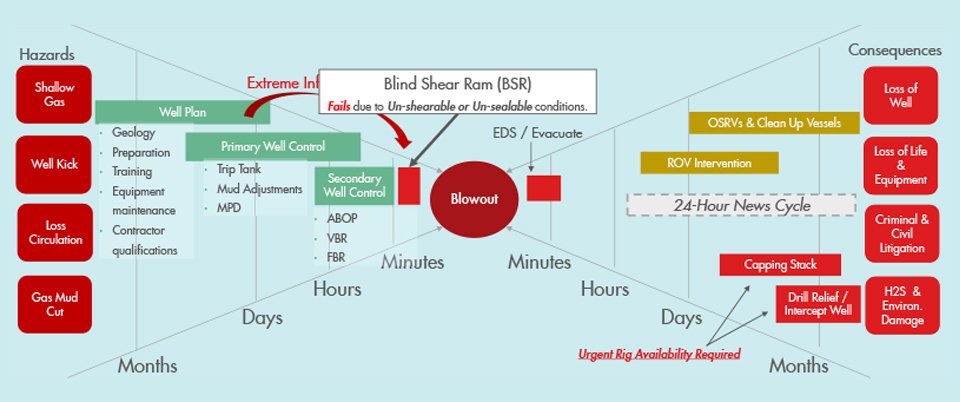

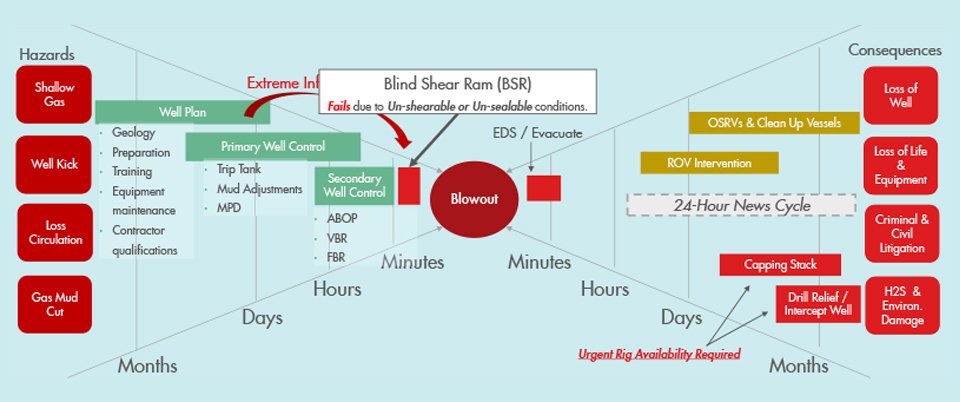

Today’s BOPs are “Blowout Preventers” as opposed to “Blowout Stoppers.” Typical blind shear rams require 30-45 seconds to close and cannot seal once full flow has been established due to a tendency for rushing wellbore fluids to washout the seals. This limitation creates an urgent situation where the driller has as little as minutes to determine whether he must sever the drill string and shut-in to prevent the potentially deadly consequences of a blowout. There is also the risk of an unshearable section of the drill string such as a tool joint, bottom hole assembly, or a large casing passing through the BOP wellbore when the blind shear ram is activated which would result in failure to close and seal.

These unshearable and unsealable situations result in a complete loss of well control, known as a blowout. The consequences of a blowout include: loss of the well, loss of life and equipment, criminal and civil litigation, and untold environmental damage including potential release of toxic gases like hydrogen sulfide (H2S.) Due to these hazards and consequences, operators frequently pay expensive rates for OSRVs, capping stacks, and other emergency teams and equipment up to and including a stand-by drilling rig for a potential intercept well.

Historical Firsts of Well Control

1st Pipe Ram BOP (1930’s)

In 1922, James Abercrombie and Harry Cameron filed a patent for the hydraulic ram-type blowout preventer which was approved in January 1926. It revolutionized the petroleum industry when installed on a wellhead, the rams could be closed off, allowing full control of pressure during drilling and production. In 1922, their Type MO blowout preventer (BOP) could withstand pressures of up to 3,000 psi. Subsequent improvements to increase the device’s capability were adapted including the development of Shear-type ram BOPs which require large additional amounts of closing force to cut through tubing occupying the wellbore. Large expensive auxiliary hydraulic actuators are frequently mounted to a BOP to provide additional shearing force.

1st Annular BOP (1940’s)

Annular BOPs (ABOPs) have been a critical component of onshore and offshore exploration. Designed by Hydril in the 1940’s, they provide a pressure barrier by sealing around tubular goods, like drill pipes, during drilling operations. ABOPs feature two moving parts: the hydraulic piston, and the rubber packing unit. The replaceable elastomer packing allows for drillers to control the pressure in the well while still rotating or moving the drill string in or out of the well.

1st Subsea completion & Spherical BOP (1950’s and 1970’s respectively)

The first subsea well completion system enabled drillers to explore the deep waters beyond the reach of self-elevated jack up rigs. Originally founded by William D. Shaffer in 1928 as Shaffer Tool Works, NL Shaffer joined with Varco, which merged with National Oilwell to become National Oilwell Varco in 2005. In addition to having developed the first subsea well completion system in the mid 1950s for Texaco and Union Oil, they developed the first spherical blowout preventer in 1972.

1st Blowout Stopper (2018)

Kinetic Pressure Control introduces the Kinetic Blowout Stopper.

The Kinetic Blowout Stopper (K-BOS) is an electrically initiated, pyro-mechanical gate valve which performs the critical function of shearing and sealing during completions and intervention well control operations. The K-BOS, has the potential to be retrofitted to existing blind shear ram cavities or may be added to the stack as a failsafe in the case of high risk Coiled Tubing, Workover, and Snubbing operations.

The K-BOS’ unique design, utilizing the power of kinetic energy, greatly limits the potential threat posed by blowouts by being able to shear and seal everything above the bit in the well, instantly with ultimate reliability.

Learn more about our technology for Completion, Intervention & Workover Applications

Learn more about our technology for Subsea Drilling Applications

Learn more about our technology for Surface Drilling Applications