HOUSTON TX: Kinetic’s 13-5/8″ bore 10,000 psi rated K-BOS (“13-10M K-BOS”) has been optimized for surface drilling and completion applications and can “Shear Anything” (work string BHAs, tool joints, and heavy casing) and “Seal Instantly”, offering a dramatic increase in shearing and sealing capability compared to typical 13-5/8″ 10,000 psi BOP stacks. The 13-10M K-BOS has been successfully qualified to meet DNVGL-OS-E101 per DNVGL-RP-A203 and meets the intent of API 16A PR2 and API S53 by reference. Like all K-BOS, the working components are isolated from wellbore fluids until activation and may be configured with materials qualified for use with up to 5,000 psi partial pressure H2S well bore fluids.

The 13-10M K-BOS is designed with the following capability:

- Shear and seal on

- Up to 8-1/4” Drill Collars (158 ppf)

- 6-5/8” drill pipe and tool joints

- All typical Wireline and Slick line

- Tubing with side load

- Materials up to MYS 165ksi

- Seal Rated from 0psi – 10,000psi working pressure

- Shear and Seal actuation time is milliseconds

- Temperature Rated from 0-350F

- Compatible with up to 5,000psi partial pressure H2S fluids

Kinetic’s proprietary seal design, that allows for reliable use of elastomeric materials compatible with up to 50% H2S fluids, is directly scalable to the 18-3/4″ size and sealing pressures of up to 20,000 psi.

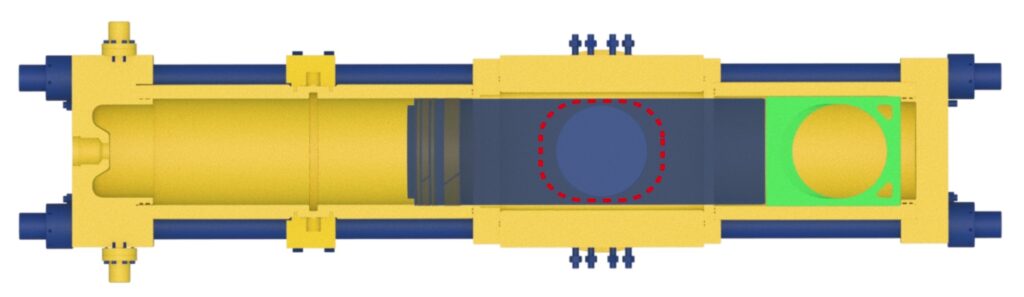

Shown Above: A cut-away view illustration of the 13-10M K-BOS as seen from above the device looking down the wellbore. The semi-transparent dark blue element has been actuated across the wellbore, and the red dashed line illustrates the seal location.

The 13-10M K-BOS has a compact design that has a height of 30 inches (studs up / flange down) or 20 inches (studs up / studs down). These dimensions, along with fully rated side outlets, allow the 13-10M K-BOS to replace most existing drilling crossflow spools resulting in an easy retrofit into almost any 13-5/8 10,000 psi BOP stack. Kinetic has also developed a range of rig-independent control system options for K-BOS surface applications, with an optional SIL3 certified control system available.

Shown Above: Successful Shear and Seal testing of the 13-10M K-BOS on a 10-3/4″ OD 0.4″ WT, P110 Casing

The qualification program that has been successfully completed included the following equipment configuration and validation activities:

- 13-5/8” bore 10,000psi RWP, 250F

- Hydrostatic shell test – PASS

- Pre-activation Accelerated Life Cycle Testing – PASS

- 1,000 pressure cycles (0-10,000psi), 60 seconds per hold cycle.

- Every 100th test LP for minimum 5 minutes then HP for minimum of 10 minutes

- Post-Fire & Pre-Fire PR2 Qualification – PASS

- LP/HP Pressure cycles at temperature:

- 3x Low temp – LP / HP holds

- 10X Continuous temp – LP / HP holds

- 1x Extreme temp – LP / HP 1hr hold

- Temperature: 30F – 240F – 250F elastomeric rating

- All materials designed for 350F

- Seal Characterization Testing – PASS

- Post activation wellbore seal system: 100 cycles to HP for 1 min, 9 cycles w/, LP 5min, HP 10min

- >50 LP/HP cycles over 3 shear tests

- API 16A Blind Shear Ram Shear & Seal Tests (6 successful shear and seal tests) – PASS

- Shear all specified tubulars with a minimum KEMS of 1.3. API 16A TR1 condition B (on bottom),

- Casing: 9-5/8’’ 47# P110 – PASS

- Casing: 10-3/4’’ 45.5# L80 – PASS

- HWDP landing string: 6-5/8’’ 63.56# Diametrically Off-center- PASS

- Seal and lock testing

- Primary seal: post shear LP/HP holds per API 16A PR2 – PASS

- Secondary seal: post shear LP/HP holds per API 16A PR2 – PASS

- Unlock & reopen testing: Unlock & retract the hammer assembly – PASS

- Shear all specified tubulars with a minimum KEMS of 1.3. API 16A TR1 condition B (on bottom),

- SIL Qualification per NOG070: Application of IEC61508 and OEC 61511 in the Norwegian petroleum industry.

“Building from our existing 5-15M K-BOS and 18-15M K-BOS designs, the 13-10M K-BOS is designed to be easily added to thousands of drilling rigs, Jack-ups and platforms,” explained Billy Gallagher, Kinetic’s COO. “Its compact design fits within the height envelope of a typical drilling spool which allows the 13-10M K-BOS to be easily retrofitted into almost any 13-5/8″ 10ksi BOP stack in the world,” he said.

Even with acute focus from drillers on well control safety, blowouts still happen. With this announcement, the 13-10M K-BOS is now available to reduce the probability of blowouts by one or more orders of magnitude in the vast majority of drilling, completions, and intervention operations.

About Kinetic Pressure Control

Kinetic Pressure Control is a leading well control technology company that designs and manufactures innovative wellhead and pressure control equipment and services. Kinetic is offering the Ultimate in Safety and Green Drilling Tech by Reimagining Well Control. Learn more about Kinetic Pressure Control Limited and their K-BOS technology at www.shearanything.com

Shear Anything | Seal Instantly | Ultimate Reliability