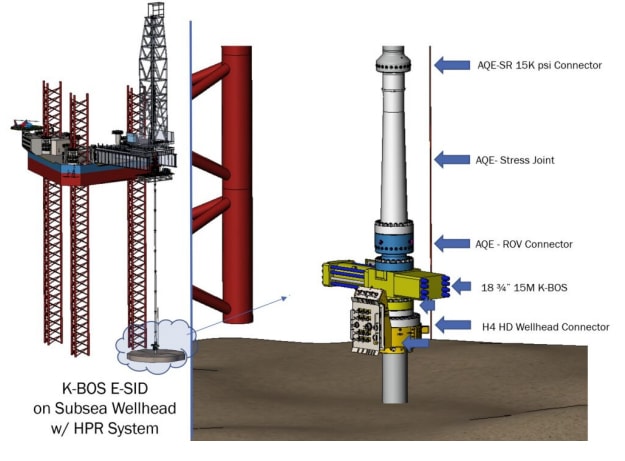

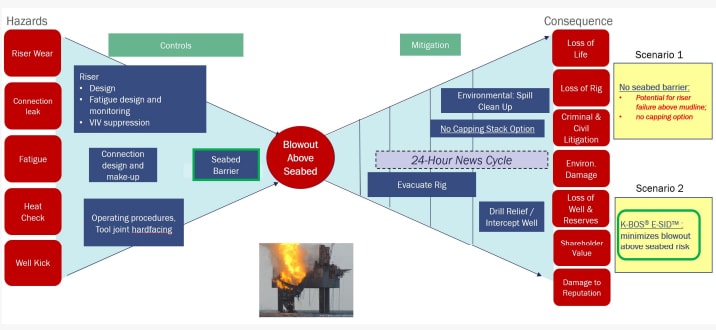

The use of high-pressure subsea riser systems enables subsea wells to be drilled efficiently using a jack-up rig, therefore allowing operators to achieve enhanced project efficiency and emission savings, compared to using a semi-sub with a mooring spread. However, the existing surface BOP system is limited, and in this application, there are no good options available to secure the well if the integrity of the riser is lost. The K-BOS E-SID can be easily integrated into the HPR system and serve as a secondary barrier latched to the subsea wellhead.

Shown above: the K‐BOS E‐SID can be easily integrated into a subsea high pressure riser (HPR) system as a seabed isolation device and provide an innovative well control barrier thus significantly reducing the risk of a MAH during operations. Image credit, Aquaterra Energy

Adding the K‐BOS at the mudline to the HPR configuration allows operators and drilling contractors to clearly demonstrate to verifiers and regulators the dramatic reduction in risk on this type of activity by providing an enhanced shearing and sealing seabed isolation / containment device. In contrast to traditional hydraulic alternatives, the K‐BOS E‐SID is compact, millisecond activation, easy to deploy and features multiple actuation options with independent or easily interfaced with exiting surface control systems.

Shown above: An illustrated “bow tie” diagram demonstrates the hazards, controls and mitigations for well control using a subsea high‐pressure riser (HPR) system. The lack of a seabed isolation device results in an unmitigated loss of well control if primary well control is lost below the surface BOP.

With the ability to stop a full flowing blowout and eliminate the release of toxic sour gas, the K‐BOS represents responsible progress in the oil and gas industry to protect communities and the environment.

The K‐BOS is considered “Green” per the EU Taxonomy.