Houston TX: A detailed analysis together with Kongsberg has shown that a 9-second EDS results in dramatically improved DP operability and can enable Shallow Water DP Ops. A K-BOS enabled dynamically positioned (DP) drilling rig can achieve a dramatically accelerated emergency disconnect sequence (EDS) compared to typical EDS times that can be as long as 70 seconds.

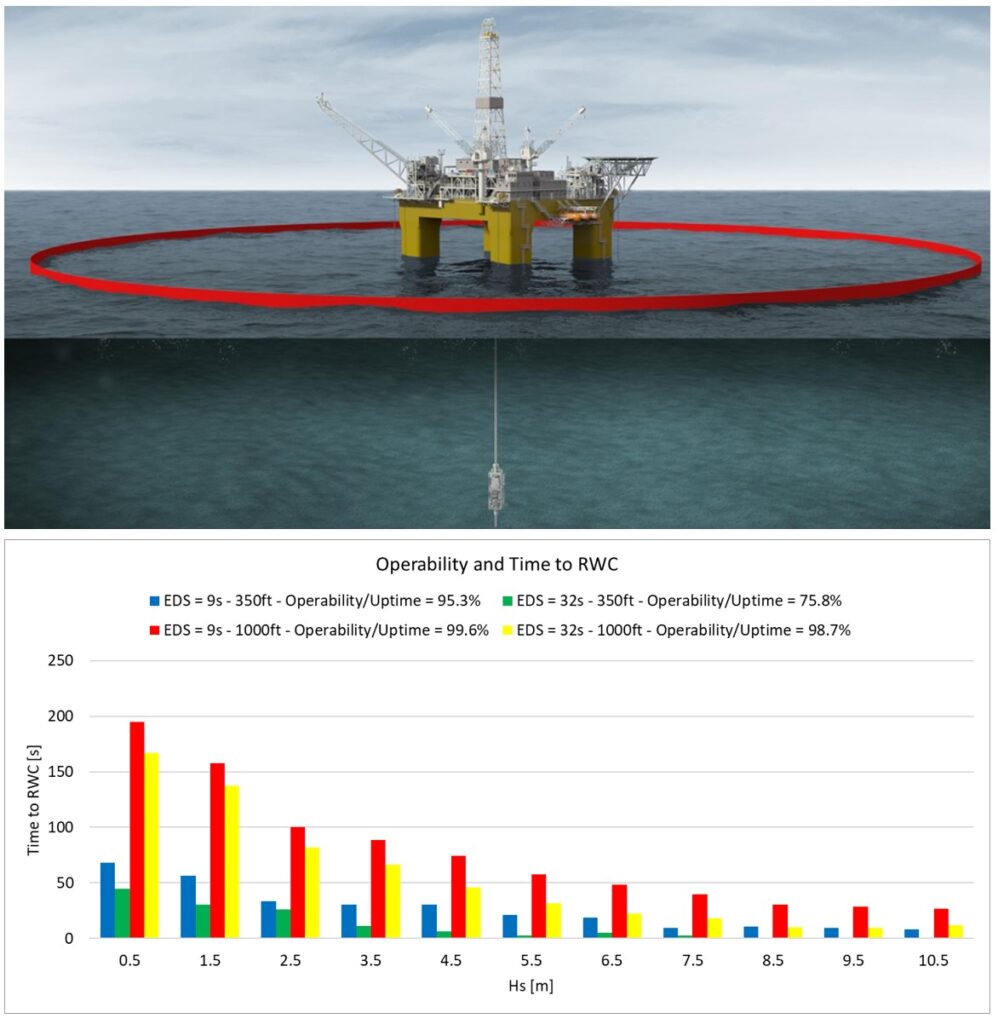

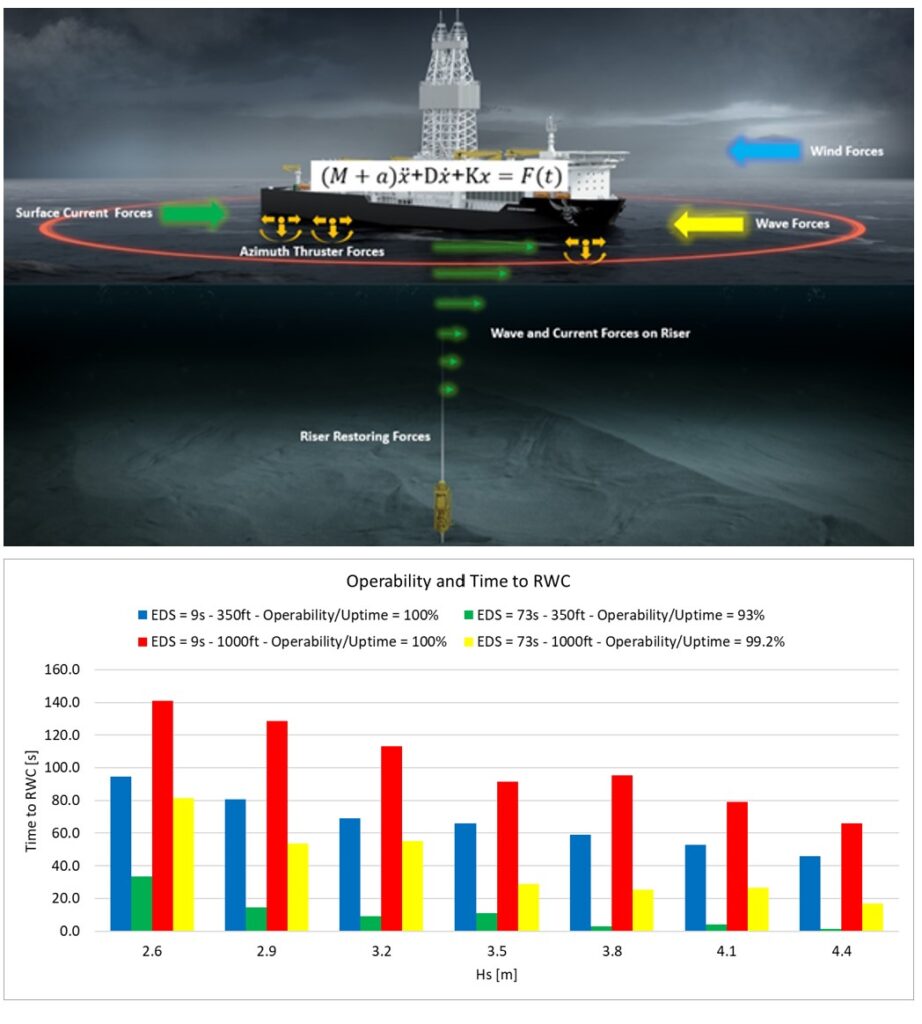

SUMMARY: The enhanced DP watch circles provided by a K-BOS optimized EDS time result in enhanced DP Operability and enable DP rigs to reduce time waiting on weather among other operational gains. An accelerated EDS also enables rigs to operate in DP mode in shallow water depths, with a 9-second EDS allowing operations in water depths of 500 ft or shallower safely and reliably. This is according to the detailed simulation and sensitivity study performed by Kongsberg, the industry leading provider of DP systems. The study fully considered all physical equipment limits including upper and lower flex joint angle and moon pool dimensions of the hull in addition to rig capability and applicable surface and subsea environmental factors.

ASSUMPTIONS: The “9-second” EDS parameter was selected for the DP Operability study based on estimates for realistic optimization of traditional EDS times achievable with K-BOS in conversations with various rig owners. Kinetic has been working with our customers on how to adapt the EDS to the capability of K-BOS and the starting point for an optimized “K-BOS EDS” for a specific rig would be to add K-BOS to the non-shear EDS and adjust the sequence from there. The K-BOS, which can shear anything and seal instantly with SIL3 reliability, provides for shear and seal at second “0” in the sequence. Then the remaining EDS function steps may be optimized considering full accumulator volume and pre-charge available to accelerate the functions. Specific rigs will have a wide variability in their starting point EDS times based on the following:

- Connector unlatch volume

- C&K connection type

- FSV close duration

- Flow path analysis

All of these factors can be adjusted and optimized, so there is value in a detailed review of the inflection point between what is possible for a given rig and what is required for a desired DP operability performance. To minimize EDS times the following adjustments may be considered:

- Connector unlatch volume: ideal connectors are 5-gal unlatch function HAR LMRP connectors

- C&K connection type: stab designs with radial seals are ideal

- FSV close duration: Several improvements for FSV close function times are available including a separate innovation from Kinetic that may be discussed upon request.

- Flow path analysis:

- Tubing design can be adjusted to minimize back-pressure using the existing system.

- For further optimization, Kinetic offers an alternative subsea control system which completes functions much faster than accumulator-based systems with SPM valves (high backpressure / low CV value).

Considering the above, Kinetic is confident that a practical solution to achieve a dramatically accelerated EDS (9-seconds or better) using the K-BOS and an optimized system. However, all these changes are not 100% required for value creation; rather, it is important to understand the EDS time required to achieve acceptable DP Operability for a specific project. For example, using the K-BOS to achieve a more conservative accelerated EDS time optimized for enhanced DP operability in water depths between 1,000 and 1,500 ft would be relatively cost efficient and may be enough in many cases.

VALUE: The benefits for a 9-second EDS identified by the study include:

- Improved watch circle/time to disconnect

- Enable safe and reliable DP Operations in shallow water depths less than 500 ft

- Reduced stress/bending moment in foundation

- Single function EDS (shear/seal) and DMAS (shear/seal)

- Low-cost alternative to anchored rig, pre-installed mooring system (anchorless operations in crowded subsea areas)

- Lower cost alternative to BOP tethering systems

Summary results of the study have been provided below. Having reviewed the study with super-major deep-water E&P operators, the projected operational gains enabled by the K-BOS for DP drilling rigs are expected to be in a range of 6% to 12% in a given year per rig.

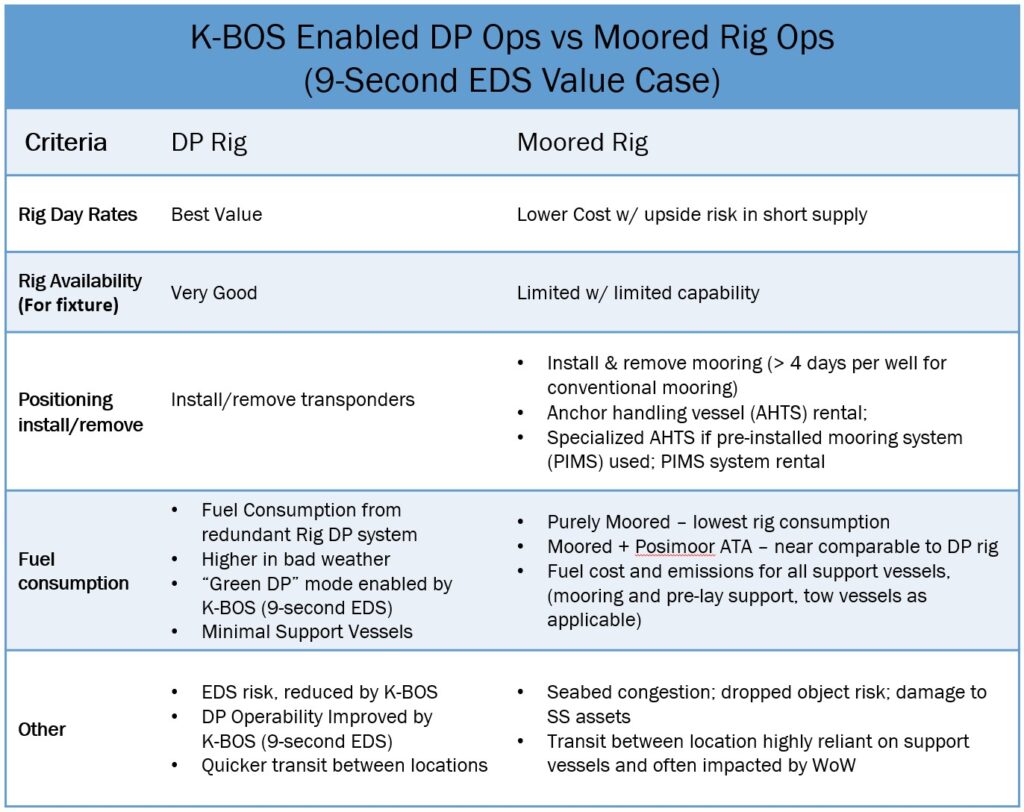

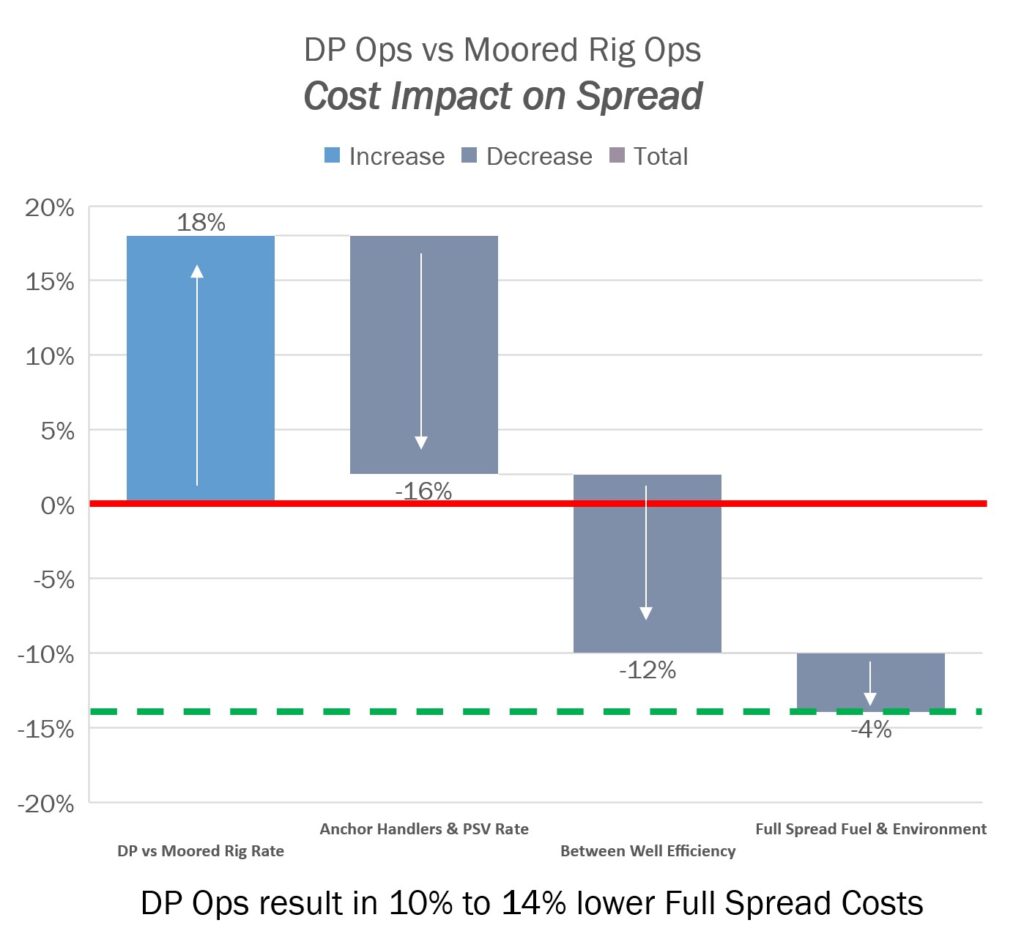

In addition to this improved performance for DP rigs in deep water, the study highlights an opportunity to utilize DP rigs in shallow water and in some harsh environments instead of moored rigs.

Further analysis provides that this can result in 10% to 14% reductions in overall spread operating costs well by well and, in cases where a particular campaign requires multiple rig moves, the overall spread efficiency results in a significant reduction in fuel consumption and a reduction in CO2 emissions.

North Sea Study Results Summary:

- 30% to 50% more time to react Vs 32 second EDS vs 0m RWC w/ 70 sec EDS

- NS Winter Weather and West of Shetland was included in “Average Weather Conditions”

GOM Study Results Summary:

- 2 to 3 x more time to react @ 350ft water depth

- >2 x more time to react @ 1,000ft water depth

- Study excluded hurricanes but included a 10-yr loop current load case

Kinetic Pressure Control is a leading well control technology company that designs and manufactures innovative wellhead and pressure control equipment and services. Kinetic is reimagining well control to deliver the ultimate in safety and green drilling technology. Learn more about Kinetic Pressure Control Limited and their K-BOS technology on our website at www.shearanything.com

Shear Anything | Seal Instantly | Ultimate Reliability