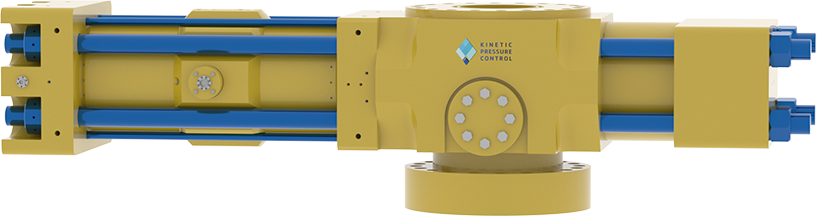

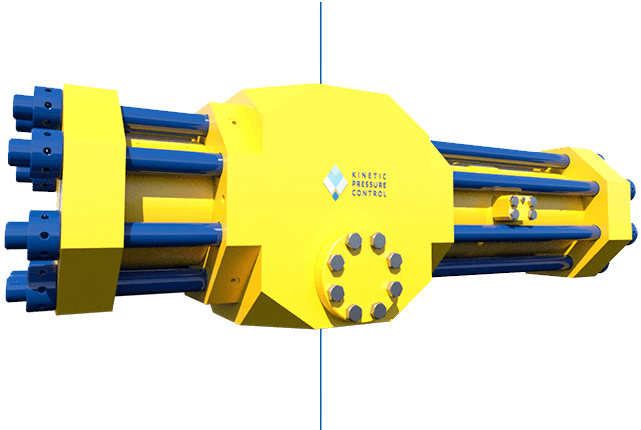

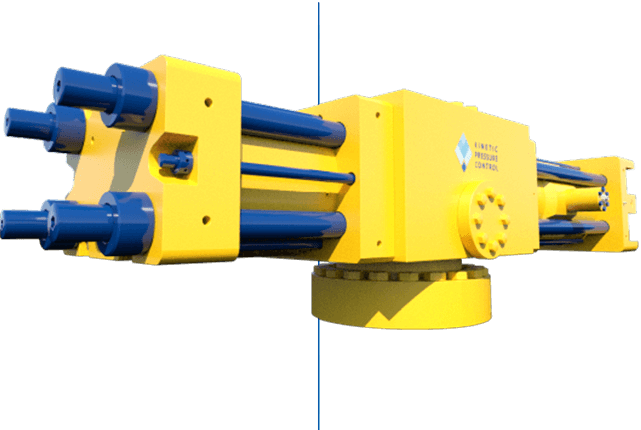

Welcome to Kinetic Pressure Control Limited

Leading Well Control

Kinetic Pressure Control is a leading well control technology company that designs, manufactures and provides innovative wellhead and pressure control equipment and services.

Innovative Technology

Kinetic is dedicated to designing, building and deploying to market innovative technologies that reduce ultimate development costs and protect the Oil and Gas Industry’s social license to operate.

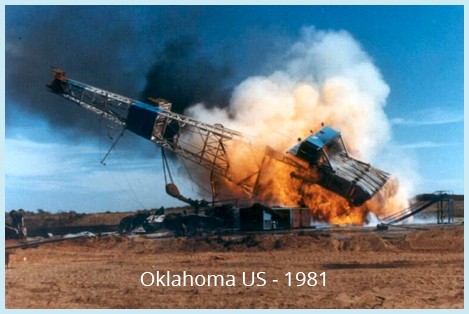

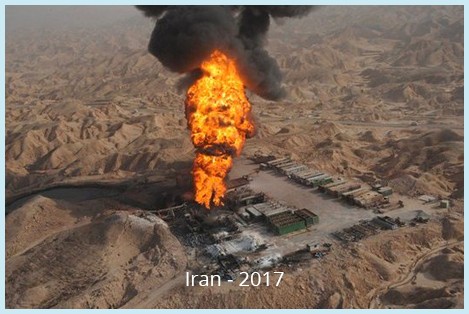

Stop Blowouts

We seek to ensure events like Macondo never happen again, offshore or on land, by developing a complementary portfolio of technologies that will revolutionize well control for the industry.