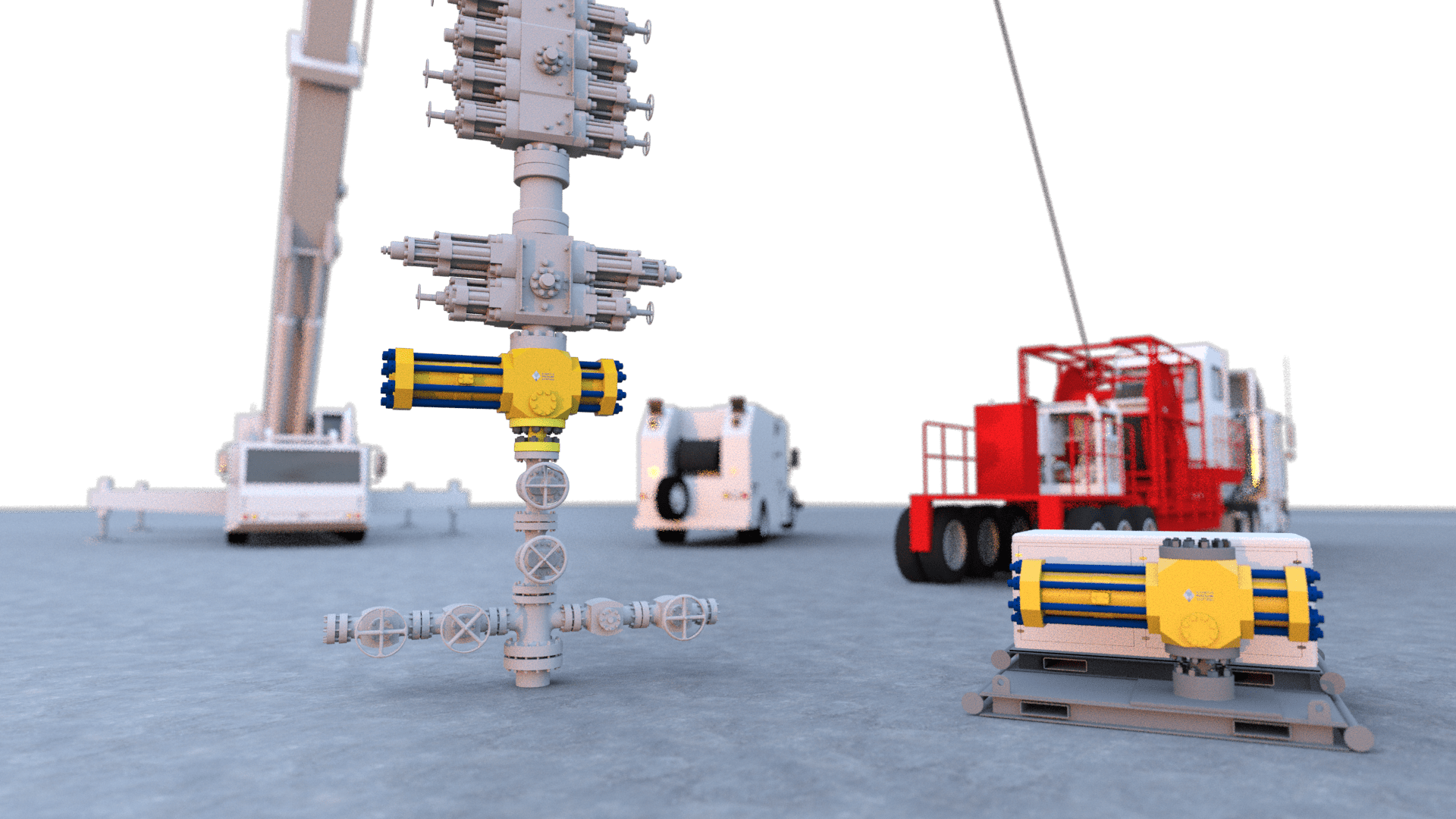

The Kinetic Blowout Stopper, or K-BOS, is an electrically initiated, pyro-mechanical gate valve which performs the critical function of shearing and sealing during completions, intervention, and workover well control operations. In these applications, the K-BOS would typically be mounted on top of the Christmas-tree as a safety head and can also be retrofitted to existing BOP cavities.

The K-BOS is the industry’s first true blowout “stopper” as opposed to current “preventers” – “think of it as the airbag for the oil & gas industry”. Kinetic has simulated a blowout under full flowing conditions and has demonstrated that the K-BOS has the ability to instantly and reliably stop the release of toxic hydrocarbons regardless of what may be across the BOP.

In the video below the K-BOS is shown mounted to the blowout simulator. In the upper right-hand corner, the well bore pressure is displayed. A nominal flow of 22,000 barrels per day is established at a flowing pressure of 4,700 psi. The K-BOS is activated and instantly shears the tubular in the bore and establishes a gas tight seal rated to 15,000 psi.

The K-BOS is designed to shear anything above the bit and seal instantly even after full flow has been established. The K-BOS is rated to shear all typical tubulars, tool joints, and BHAs used for a given API bore size and can also cleanly shear wireline in the slack condition. The rapid kinetic shearing action leaves a clean fish with minimal deformation and allows the K-BOS to shear and seal in miliseconds with unmatched reliability.

4-1/16” K-BOS 3-1/8” Drill Collar

5-1/8” K-BOS 3-1/2” Drill Collar

5-1/8” K-BOS 3-1/2” OD Drill Collar

4-1/16” K-BOS 5/16” Wireline

In the past, the Industry’s emergency well control systems lagged reliability standards of comparable safety functions in other industries. The K-BOS utilizes the highest reliability components and methodologies which have each been field proven in safety critical applications during more than 20 years of operations.

The K-BOS’ ability to continuously self-diagnose faults and positively confirm functional availability in real time and while offline to drilling operations creates an opportunity to reduce testing related non-productive time while increasing emergency well control system reliability by 3 to 4 orders of magnitude.